In the lifecycle of a deployed IoT device, the sensor is often the mechanical weak point. For applications like Tire Pressure Monitoring Systems (TPMS) or logistics trackers, a sensor must withstand years of constant movement without failure.

Introducing the KD1902, an upgraded Omnidirectional SMT Vibration Trigger Sensor from Shenzhen Kingdta Technology. Building on the ultra-low power architecture of the KD19xx series, the KD1902 is engineered for extreme durability, boasting a service life of over 2,000,000 cycles.

1. Engineered for Endurance

While standard vibration switches may fail after prolonged exposure to rough environments, the KD1902 utilizes a specialized vacuum core-shell process and premium electroplating. This allows it to endure:

- Vibration Life: ≥ 2,000,000 triggers.

- Temperature Extremes: Functions reliably from -40°C to +85°C.

- Solder Heat: The housing withstands up to 400°C short-term, making it robust during reflow assembly.

This level of durability makes it the preferred choice for Automotive Electronics and Industrial Asset Tracking.

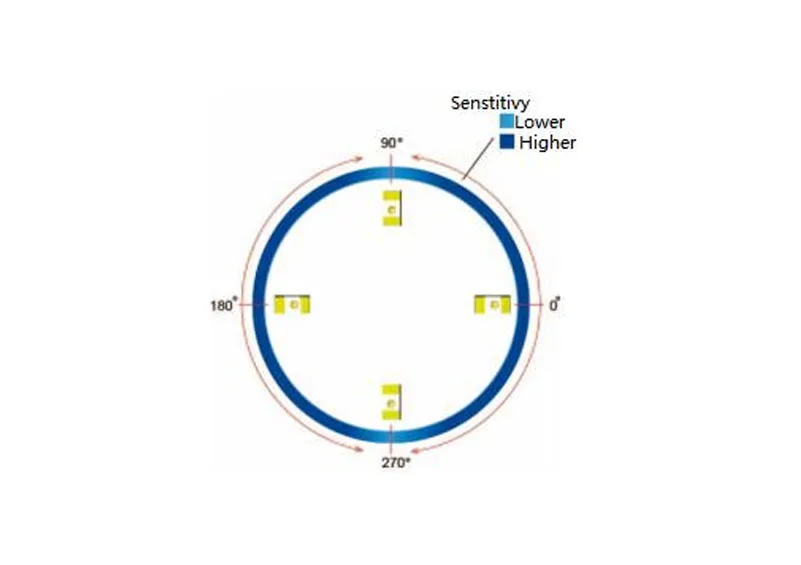

2. 360° Omnidirectional Triggering

The KD1902 replaces legacy mercury switches and bulky spring sensors with a miniature ball-contact structure. It features no “blind spots.”

- Mechanism: A free-moving internal sphere bridges the electrode gap upon movement.

- Response: It is most sensitive along the four major axes (0°, 90°, 180°, 270°) but triggers effectively from any random vibration angle.

Interactive Demo: 360° Detection Logic

Use the simulation below to visualize how the KD1902 detects motion from any direction to trigger a system wake-up.

Sensor Telemetry

3. Passive “Zero-Power” Architecture

Like its sibling the KD1901S, the KD1902 is a passive component. It requires no active power supply to monitor motion.

- Standby Current: Effectively 0A (High Impedance).

- Operating Current: Determined by your pull-up resistor (typically micro-amps or nano-amps).

- Voltage Range: Versatile support for 0.5V to 36V DC.

This makes it the ultimate solution for battery-powered devices that need to sit on a shelf for years and wake up instantly when moved.

4. Design & Integration Guide

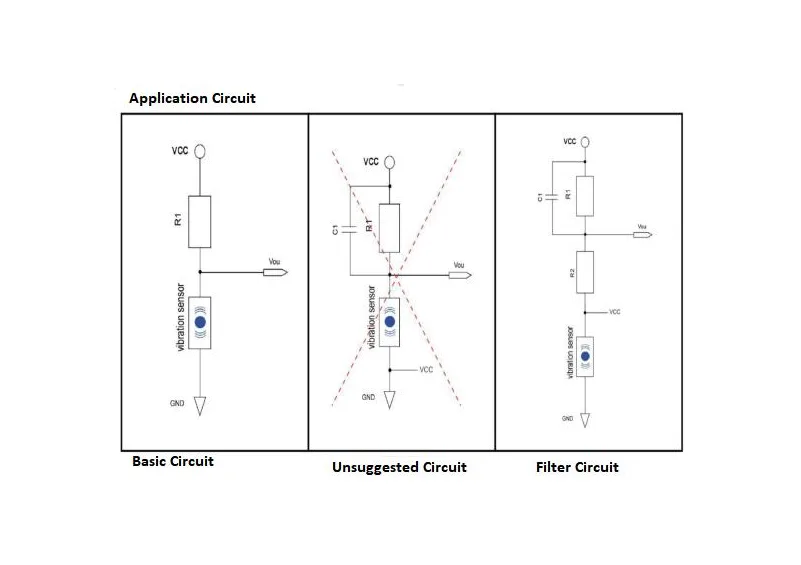

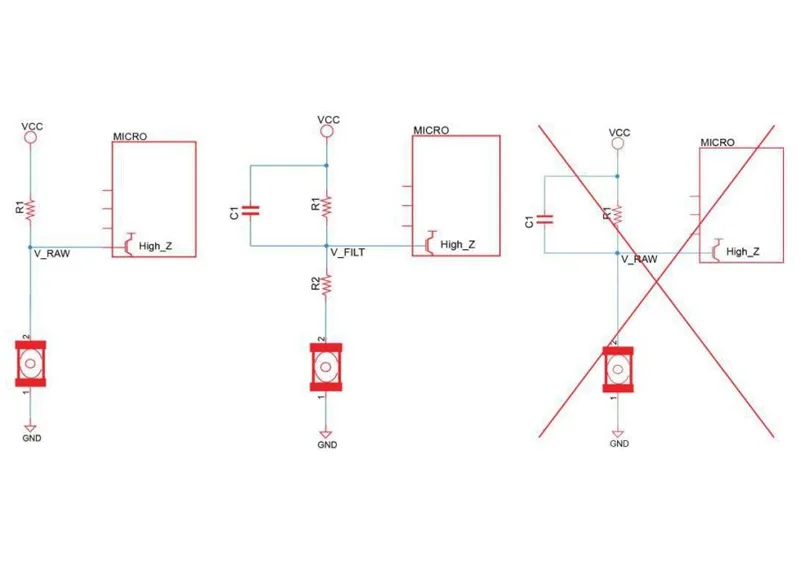

Integrating the KD1902 is simple, but optimal performance requires correct circuit design.

Recommended Circuit Configuration

- Pull-Up Resistor: Connect the sensor to an MCU GPIO with a pull-up resistor.

- Noise Filtering: For high-sensitivity applications, the sensor might trigger on micro-vibrations. To filter this out:

- Hardware: Add a Capacitor (C1) and Resistor (R2) to form a low-pass filter (see datasheet).

- Software: Implement a debounce algorithm in firmware to count pulses before waking the main CPU.

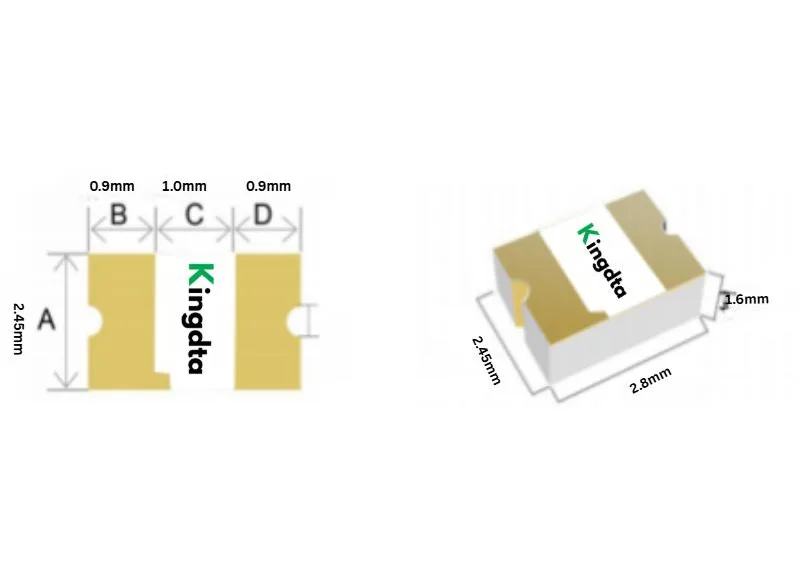

5. Manufacturing Specifications

The KD1902 is built for high-speed SMT assembly lines.

- Package: Miniature SMD (Surface Mount).

- Sealing: 100% factory tested, hermetically sealed against dust and water.

- Reflow Soldering: Compatible with standard lead-free profiles (Peak 260°C).

6. Key Applications

Due to its extended 2-million-cycle lifespan, the KD1902 is ideal for:

- TPMS (Tire Pressure Monitoring): Activating sensors only when wheels rotate.

- Smart Remote Controls: Backlight activation upon pickup.

- RFID Smart Tags: Logistics tracking that sleeps during storage.

- Wearables: Step counting or tap detection.

结论

When reliability cannot be compromised, the KD1902 delivers. It combines the ease of SMT manufacturing with the ruggedness required for automotive and industrial use cases, all while consuming virtually zero power.

Contact Kingdta today to integrate the KD1902 into your next design.