In the rapidly evolving world of smart home appliances and portable electronics, safety is not just a feature—it is a requirement. Whether it is an electric heater falling over or a service robot navigating a slope, detecting device orientation instantly is critical.

Today, we are diving deep into the KD1918S-30, a revolutionary SMD Photoelectric Ball Tilt Switch designed by Shenzhen Kingdta Technology. Unlike bulky, mechanical switches of the past, the KD1918S-30 offers high-precision, 360° omnidirectional detection in a compact surface-mount package.

1. How It Works: Optical Precision vs. Mechanical Chaos

The core innovation of the KD1918S-30 lies in its internal structure. Traditional tilt switches often rely on physical contacts that can oxidize or suffer from contact bounce. The KD1918S uses a photoelectric ball mechanism.

The Logic:

- Upright State (High Output): When the device is vertical, the internal conductive ball aligns perfectly with the optical path. The phototransistor conducts, sending a High Level signal to your MCU.

- Tilted State (Low Output): As soon as the device tilts beyond the threshold (30°±10°), the ball rolls away, blocking the light path. The output instantly switches to Low Level.

This “Non-Contact” design ensures an electrical lifespan of over 1,000,000 cycles.

Interactive Demo: See the KD1918S in Action

Drag the slider below to simulate the tilt angle and watch how the sensor responds.

Interactive Logic Demo

KD1918S-30Drag slider to rotate. Trigger threshold: > ±30°

2. Technical Deep Dive: Key Specifications

The KD1918S-30 is built for integration. It supports vertical flip detection and horizontal tilt, making it a complete attitude monitoring solution.

Electrical Characteristics

| Parameter | Value | Note |

|---|---|---|

| Supply Voltage (Vcc) | 4.5V – 5.5V | Standard 5V logic |

| Operating Current | 6 – 10mA | Low power consumption |

| Response Time | 5ms – 100ms | Rapid detection |

| Output Type | Digital | Open-Collector (Requires Pull-up) |

Precision Triggering

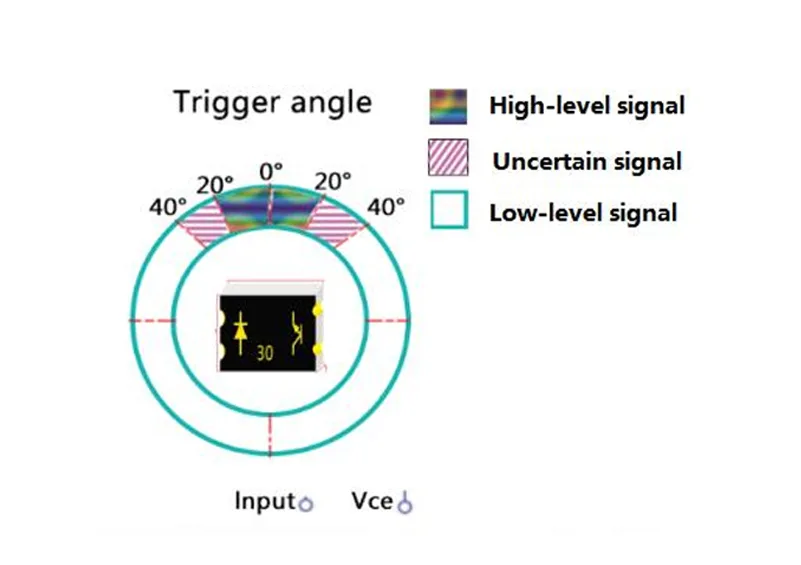

The datasheet specifies distinct zones to prevent false alarms:

- 0° to ±20°: Stable High Output (Safe Zone).

- ±20° to ±40°: Transition Zone.

- > ±40°: Stable Low Output (Trigger Zone).

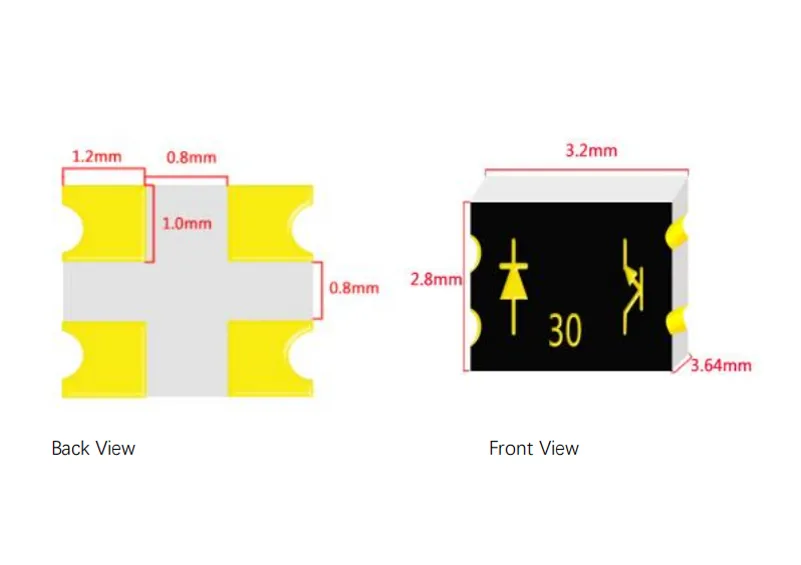

3. Designed for Manufacturing: SMD & Soldering

One of the biggest advantages of the KD1918S-30 is its SMD (Surface Mount Device) form factor. This saves valuable PCB space compared to through-hole components, making it ideal for miniaturized designs like wearables or compact IoT sensors.

Soldering Guidelines:

- Reflow Soldering: Peak temperature of 255°C ±10°C (Max exposure < 5 seconds).

- Manual Soldering: Max 330°C for < 3 seconds.

- Note: Do not reflow more than twice, and allow full cooling before handling to avoid mechanical stress.

4. Rugged Reliability

Kingdta has engineered the KD1918S-30 to withstand harsh environments. The unit features a core-shell structure manufactured with a vacuum process, ensuring the internal optical components are isolated from the outside world.

- Temperature Range: Operates from -40°C to +85°C.

- Salt Mist Test: Passed 72 hours at 95% RH.

- Sealing: Fully waterproof and dustproof.

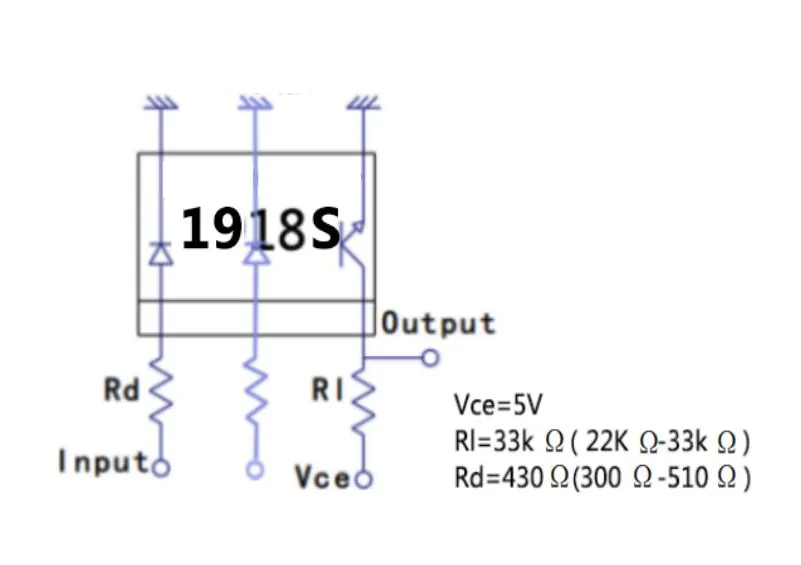

Engineering Tip: The internal circuit includes a 3kΩ pull-up resistor (Rl) and a 430Ω input resistor (Rd). It is designed to connect directly to an MCU GPIO.

5. Applications

Where should you use the KD1918S-30?

- Safety Protection: Auto-shutoff for electric heaters, fans, and humidifiers.

- 智能家居: Air purifiers and interactive smart products.

- Robotics: Educational and service robots (detecting falls or steep inclines).

- Charging Piles: Detecting if a charging post has been impacted or tilted.

结论

The KD1918S-30 represents the next generation of tilt detection. By combining the precision of optics with the convenience of SMD packaging, it offers a “install-and-forget” solution for safety-critical applications.