In the realm of electromechanical components, mechanical fatigue is the enemy. For standard consumer electronics, a sensor that lasts a few years is sufficient. But for industrial asset trackers, automotive safety systems, or smart meters installed for a decade, you need components that refuse to quit.

Shenzhen Kingdta Technology presents the KD1912, the flagship of endurance in the SMT vibration sensor lineup. With a massive rated lifespan of ≥ 5,000,000 cycles, it is engineered for applications where failure is not an option.

1. Unmatched Durability: 5 Million Triggers

The defining feature of the KD1912 is its longevity. While standard market alternatives often fail around 100k to 500k cycles, the KD1912 utilizes advanced materials and a vacuum-sealed core-shell structure to achieve 5 million reliable triggers.

This makes it perfect for high-frequency environments, such as:

- Machinery Condition Monitoring: Detecting continuous vibrations in industrial equipment.

- Smart Logistics: Tracking packages that undergo constant handling.

- 汽车 Systems exposed to perpetual road vibration.

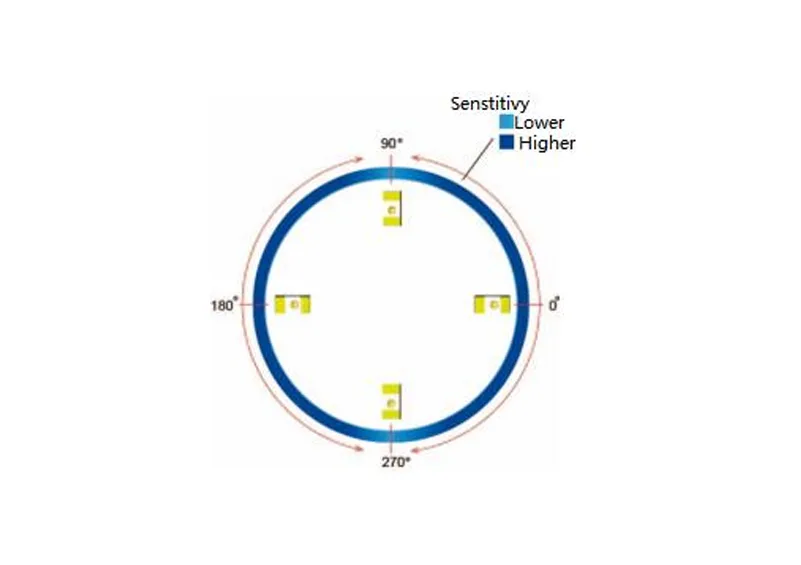

2. Omnidirectional “Wake-Up” Technology

Like its predecessors, the KD1912 solves the power consumption paradox in IoT: How do you keep a device ready without draining the battery?

The Solution: The sensor acts as a passive hardware switch.

- Static: Ideally 0 power consumption (High Impedance).

- Motion: When moved in any direction (360° coverage), the internal ball closes the circuit, sending a pulse to wake the MCU.

3. Electrical & Environmental Specs

Despite its ruggedness, the KD1912 remains a precision component compatible with modern low-voltage logic.

| 特点 | 规格 | Note |

|---|---|---|

| 工作电压 | 0.5V – 36V DC | Wide compatibility |

| Current Rating | 50nA – 10mA | Ultra-low power |

| Temperature | -40°C to +85°C | Harsh environment ready |

| Sealing | Hermetically Sealed | Waterproof & Dustproof |

4. Application Circuit Design

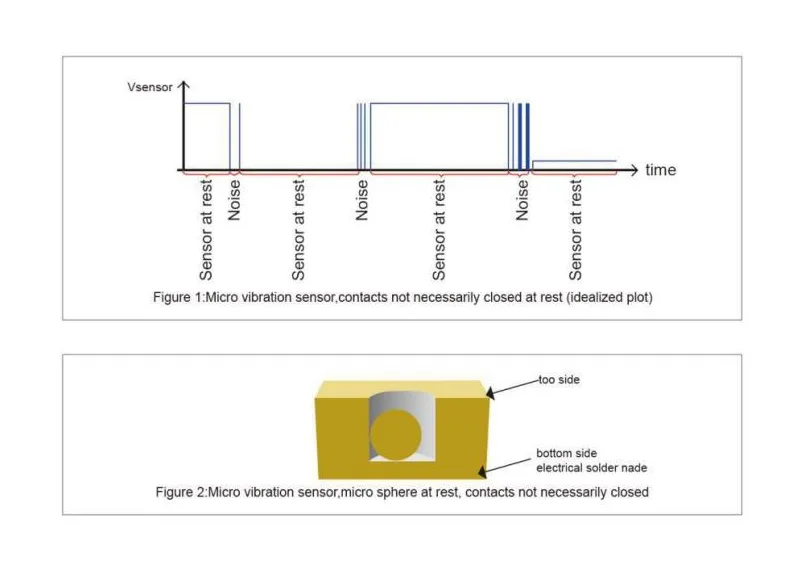

To get the most out of the KD1912, correct circuit implementation is key. The output is a series of rapid pulses (micro-interruptions) rather than a steady state change.

- The Pull-Up: Connect the sensor between Ground and an MCU Pin pulled High.

- Debouncing: Because the KD1912 is highly sensitive, raw signals can be “noisy.”

- Hardware approach: Use the recommended RC filter (Capacitor C1 + Resistor R2) to smooth transients.

- Software approach: Implement a counter in firmware. Only wake the full system if N pulses are detected within T milliseconds.

Interactive Simulation: Filter Logic

Use the demo below to see how “Filtering” prevents false alarms from minor vibrations versus sustained motion.

MCU Wake-Up Logic Simulator

5M Cycles RatedSimulates continuous vibration input to test filter logic.

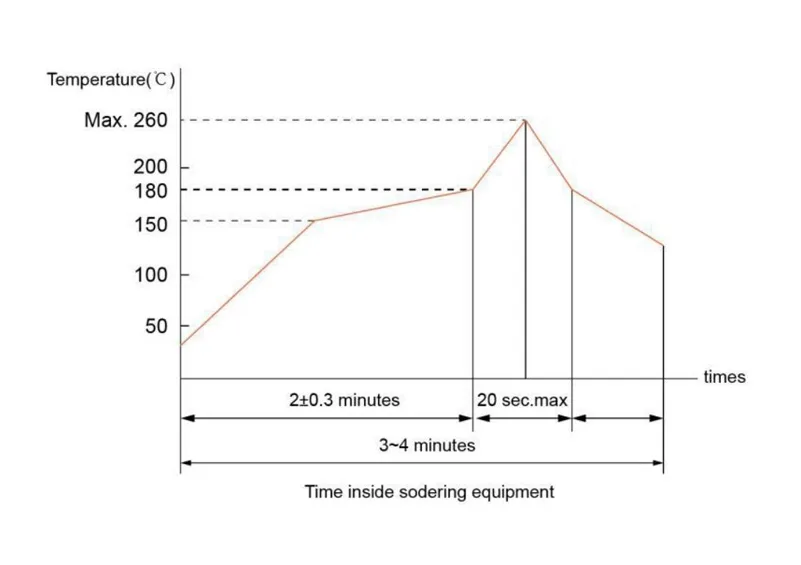

5. Manufacturing Guidelines

The KD1912 is an SMD component designed for automated assembly. However, due to its internal mechanical nature, specific care is needed:

- Reflow Soldering: Follow the standard lead-free profile.

- Preheat: 180°C (2 mins).

- Peak: 260°C (Max 5 seconds).

- Flux Caution: Do not use strong acid or alkaline flux, as this can compromise the seal over time.

- Cooling: Allow the device to cool fully before any mechanical handling to prevent internal stress.

6. Where to Use the KD1912?

The premium endurance of this sensor qualifies it for:

- Smart Metering: Tamper detection for utility meters (water/gas/electric) expected to last 10+ years.

- Animal Tracking: Smart collars for livestock that move constantly.

- Bicycle/E-Bike Alarms: Detecting movement for anti-theft systems.

- Remote Controls: Power-saving wake-up features.

结论

The KD1912 combines the convenience of SMT assembly with industrial-grade durability. If your product demands a sensor that can withstand millions of interactions without degrading, this is the solution.

Need a high-endurance sample? Contact Kingdta Technology today.